The patterned stainless steel sheet is made by sliding the sheets under sanding brushes or synchronized casting rollers. It is the process of obtaining a beautiful pattern on one or both sides of the sheet, allowing for a striking finish. This process is not only to create a good pattern finish but also to strengthen the polish. With this procedure, the scratches are easily propagated without losing incredible durability.

Patterned steel has many different uses for architectural projects, but it covers catering, elevators, floors, and even recreation areas.

Patterned steel design

The patterned steel design makes it unique with hundreds and thousands of options, affordable prices, custom lengths, and a cutout design that can make anything look luxurious. Aesthetically, the steel finishes can be random and symmetrical, keeping it modern and attractive. There are no flaws in this product like canned oil, and the improved optical flatness makes this material perfect for coatings. The growth of patterned stainless steel over the past few years has been incredible. It has become prevalent in the fashion and hospitality industries, from hotels that create a sense of luxury by stepping into decorative patterned steel, high caliber brands that use it in their catwalk presentations. There is a reason for this for architects and designers.

As a direct result of this material’s durability and strength, you will also experience savings benefits in the long run. Processing the samples will help hide all those little marks and general wear and tear, unlike smooth, polished metals, which often have the slightest relief. Longer life means there is no need to replace applications such as gates, poles, and elevators.

The patterned stainless steel sheet’s sampling process also provides a reduced contact area, so it is ideal for increasing the workflow in things like cameras, food, and beverage machinery. This means that the reduced contact area reduces friction issues, which are often the reason for slower production flow.

These finishes have been proven, tested and reliable for over 40 years due to their durable and vandal-resistant properties. Although industries are continually changing, materials and patterned stainless steel are improving more and more.

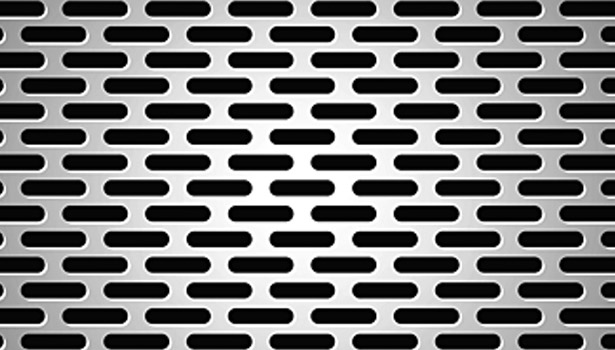

Perforated plate

A perforated sheet is a sheet steel product fed into a machine to make round holes (or other designs). These holes can be straight lines or staggered to increase the number of openings. Usually, the edge of the sheet has a boundary where the holes do not pierce; this adds stability to the list. The metal removed from the holes can be recycled, but this also increases the product’s cost. The larger the size of the hole of your decorative perforated sheet metal, the greater the volume of waste, and hence the prices can increase.

However, several offices and industries are constructed using either patterned or decorative perforated sheet metal. For instance, industries such as construction, food and beverage, architecture, material development, chemical and energy, and more, are nowadays constructed using these sheet metals.